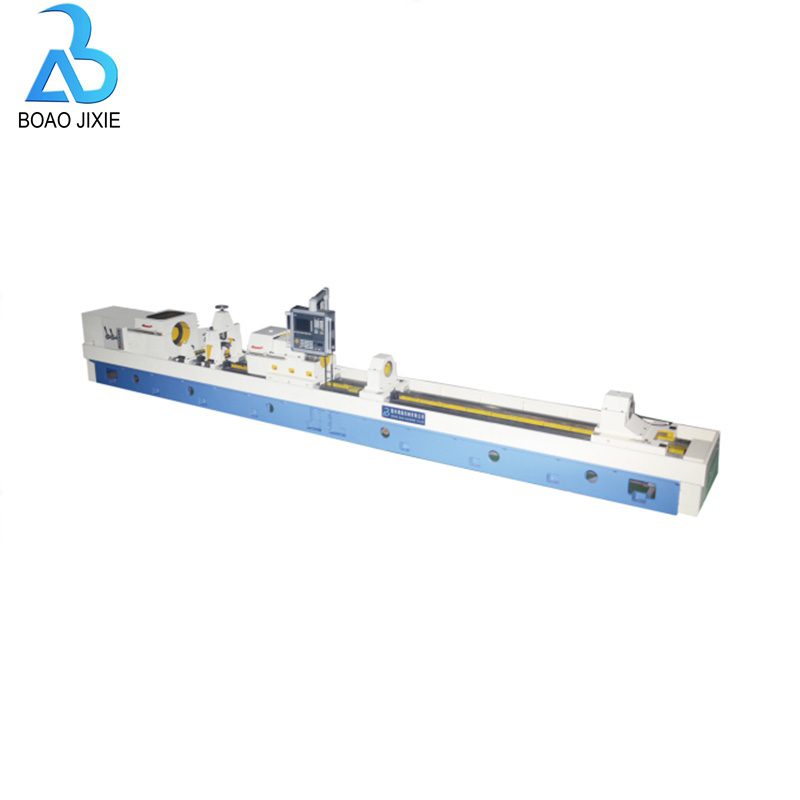

Mesin boring bolongan jero tugas abot sing apik kanthi alat pengeboran

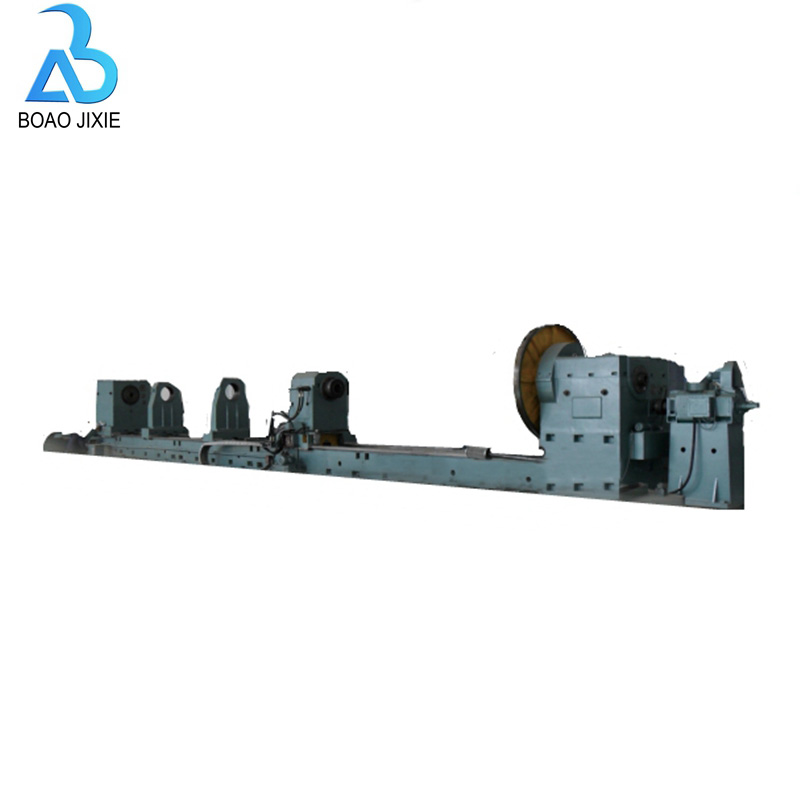

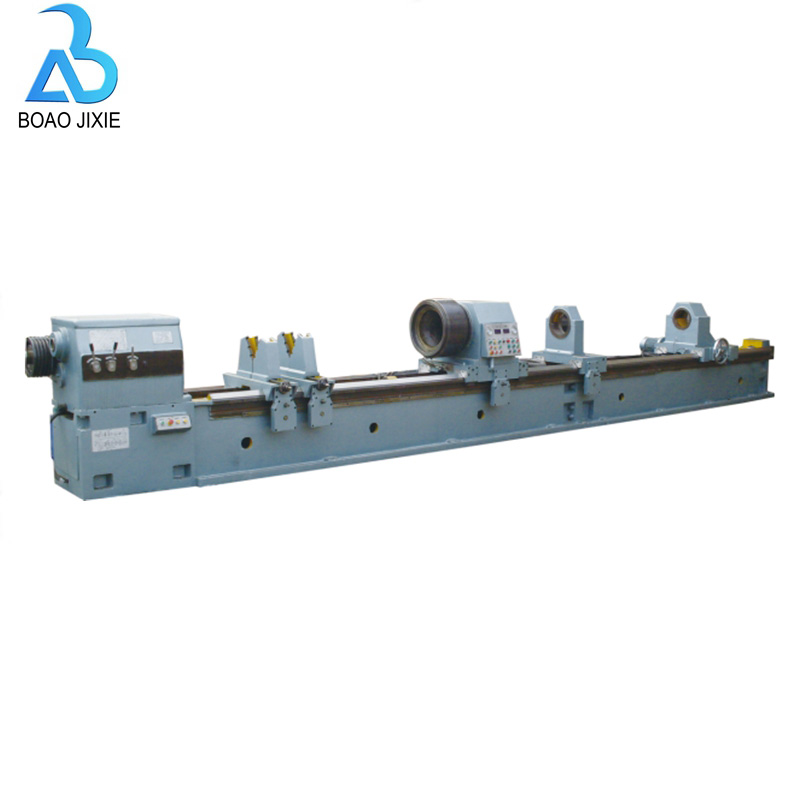

Deskripsi Produk

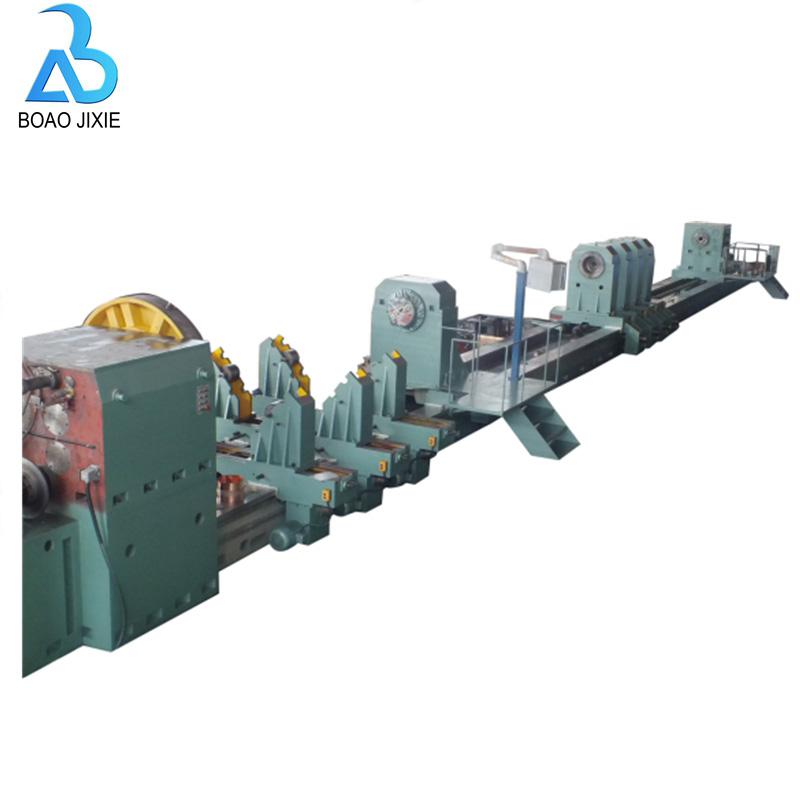

mesin T2180 utamané kanggo Processing bagean silinder tugas abot, kayata ngebur, mboseni, ngembangaken, roller burnishing lan trepanning, etc workpiece wis katahan alon puteran, alat kanthi cepet Rotary nalika dipakani.Kejabi mesin liwat-bolongan, uga bisa ngolah bolongan langkah lan bolongan wuta.Mesin iki digunakake ing macem-macem, jinis proses bisa dipilih adhedhasar panjaluk nyata.

Nalika ngebur, mesin nganggo jinis penghapusan chip internal BTA, feeder minyak nyedhiyakake cairan pemotongan kanggo mbusak kripik metu saka mburi bar pengeboran.Nalika push-mboseni, Cairan nglereni tekan area nglereni liwat bolongan cilik saka feeder lenga utawa bolongan amba ing mburi bar mboseni.

Kripik wis flushed metu saka mburi headstock.Nalika trepanning, alat khusus, toolbar lan piranti clamping kudu dilengkapi, chip wis dibuwang dening jinis aman external.

Mesin iki dirakit nganggo kothak pengeboran, sing entuk rotasi dobel workpiece lan alat, tumindak siji uga kasedhiya adhedhasar panjaluk nyata.Nalika workpiece mbutuhake kacepetan rotary ngisor, efficiency proses lan kualitas bisa njamin.

Headstock nggunakake chuck papat rahang tugas abot kanggo ngunci workpiece, liyane anteng kanggo ndhukung lan feeder lenga kanggo clamping dening meksa hydraulic.Feeder minyak nggunakake struktur sumbu utama sing nambah kapasitas beban lan akurasi rotasi.Awak amben nduweni kaku banget, tahan nyandhang sing apik lan kemampuan nahan presisi sing dhuwur.Alat dipakani nganggo motor servo AC kanggo nyadari regulasi kacepetan tanpa langkah.Headstock nggunakake motor DC kanthi regulasi kacepetan tanpa langkah.Kothak pengeboran didorong dening motor daya gedhe, kanthi kacepetan diatur kanthi shift gear.

Sistem hidrolik nduweni kontrol sing akurat nalika clamping lan mbenakake workpiece, sing nduweni stabilitas lan presisi sing dhuwur.Kabeh paramèter operasi ditampilake kanthi tampilan meter, clamping workpiece lan operasi banget aman, cepet lan stabil.Mesin kasebut nggunakake kontrol PLC kanthi antarmuka manungsa-mesin, gampang dioperasikake.

Spesifikasi

| NO | barang | Katrangan | |

| 1 | Model | T2280 | T2180 |

| 2 | Kisaran diameteripun pengeboran |

| Φ60mm-Φ150mm |

| 3 | Max boring kisaran diameteripun | Φ800 mm | Φ800 mm |

| 4 | Range ambane mboseni | 1000 - 15000 mm | 1000 - 15000 mm |

| 5 | Workpiece clamping kisaran diameteripun | 320-1250 mm | 320-1250 mm |

| 6 | Mesin spindle dhuwur tengah | 1000 mm | 1000 mm |

| 7 | Rentang kacepetan rotasi spindle headstock | 3-120r / min | 3-120r / min |

| 8 | diameteripun bolongan Spindle | 1-225r / min | 1-225r / min |

| 9 | Spindle diameter bolongan taper ngarep | Φ130 mm | Φ130 mm |

| 10 | Daya motor headstock | 140# | 140# |

| 11 | Daya motor kothak bor |

| 30KW |

| 12 | Drill kothak diameteripun bolongan kumparan |

| 130 mm |

| 13 | Lubang taper ngarep dia.saka kothak bor |

| Φ85mm (1:20) |

| 14 | Kisaran kacepetan kothak bor |

| 16-270r / min |

| 15 | Range kacepetan Feed | 5-2000mm/menit (stepless) | 5-2000mm/menit (stepless) |

| 16 | Feeding carriage kacepetan cepet | 2m/min | 2m/min |

| 17 | Feed daya motor | 11KW | 11KW |

| 18 | Feed carriage daya motor cepet | 36N.M | 36N.M |

| 19 | Daya motor pompa hidrolik | N=1,5 KW | N=1,5 KW |

| 20 | Rated tekanan kerja sistem hidrolik | 6,3 Mpa | 6,3 Mpa |

| 21 | Daya motor pump cooling | N=7.5KW(2 kelompok)5.5KW(1kelompok) | N=7.5KW(2 kelompok)5.5KW(1kelompok) |

| 22 | Rated tekanan kerja sistem pendingin | 2,5 Mpa | 2,5 Mpa |

| 23 | Aliran sistem pendinginan | 300, 600, 900L / min | 300, 600, 900L / min |

| 24 | Sistem kontrol CNC | Siemens 808 utawa KND | Siemens 808 utawa KND |